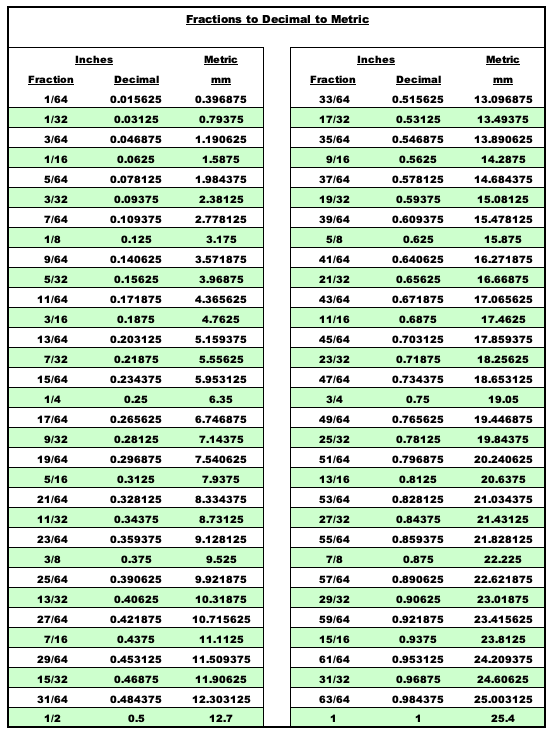

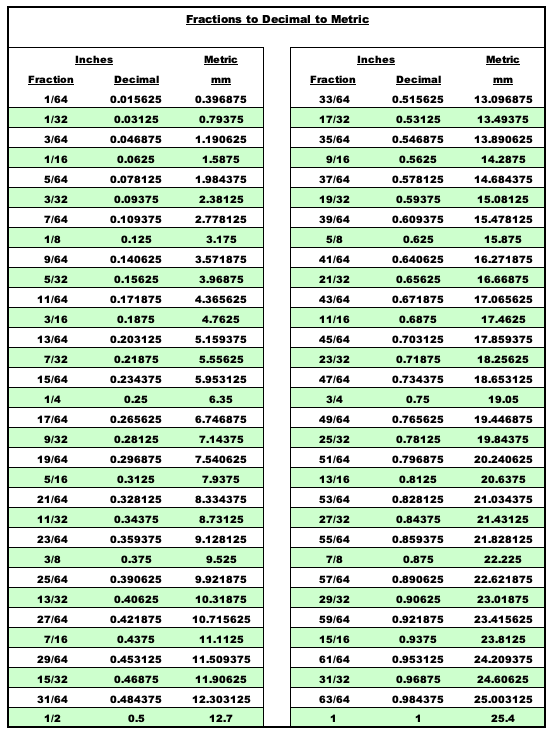

Mechanical Tolerance Chart Data. The following Engineering calculator will show the plus and minus tolerance for the specific ISO 286 Shaft tolerance data. Enter your desired preferred tolerance grade and the nomial size. Also see Table of Hole Tolerances per. Preferred tolerance grade ISO 286; International Tolerance Grades. ISO Tolerances for Shafts (ISO 286-2) Nominal Shaft Sizes (mm) over 3. Comparision table Alu comparison table Carbide equivalent chart. Inch - metri Conversion Charts Periodic Table of elements.

The Rubber Manufacturers Association (RMA) has developed tolerance tables with ranges to provide communication between user and provider across a wide range of industries. These are helpful when designing and producing a part. You can also consult the RMA article on factors affecting tolerances of molded rubber products.

- RMA Molded Tolerances

- RMA Extrusion Tolerances

- Table 12.

Summary of RMA Drawing Designations Extruded Rubber Products - Table 13.

Standard Cross-Sectional Tolerance - Table 16.

Cut Length tolerance for unspliced extrusion - Table 18.

Spliced Length Tolerances - Table 20.

Tolerances on Internal Dimensions of Mandrel-Supported Extrusions

Metric Tolerances (mm)

| Nominal Dimension | A1 | A2 | A3 | A4 |

| above | up to and

including | Fixed | Closure | Fixed | Closure | Fixed | Closure | Fixed | Closure |

| 0 | 10 | 0.1 | 0.13 | 0.16 | 0.2 | 0.2 | 0.32 | 0.32 | 0.8 |

| 10 | 16 | 0.13 | 0.16 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.9 |

| 16 | 25 | 0.16 | 0.2 | 0.2 | 0.32 | 0.32 | 0.5 | 0.5 | 1 |

| 25 | 40 | 0.2 | 0.25 | 0.32 | 0.4 | 0.4 | 0.63 | 0.63 | 1.12 |

| 40 | 63 | 0.25 | 0.32 | 0.4 | 0.5 | 0.5 | 0.8 | 0.8 | 1.25 |

| 63 | 100 | 0.32 | 0.4 | 0.5 | 0.63 | 0.63 | 1 | 1.1 | 1.4 |

| 100 | 160 | 0.4 | 0.5 | 0.63 | 0.8 | 0.8 | 1.25 | 1.25 | 1.6 |

160 & over

(Multiply by) | x .004 | x .005 | x .005 | x .008 | x .008 | x .010 |

Inch Tolerances (in)

| Nominal Dimension | A1 | A2 | A3 | A4 |

| above | up to and

including | Fixed | Closure | Fixed | Closure | Fixed | Closure | Fixed | Closure |

| 0 | 0.40 | 0.004 | 0.005 | 0.006 | 0.008 | 0.008 | 0.013 | 0.013 | 0.032 |

| 0.40 | 0.63 | 0.005 | 0.006 | 0.008 | 0.010 | 0.010 | 0.016 | 0.016 | 0.036 |

| 0.63 | 1.00 | 0.006 | 0.006 | 0.010 | 0.013 | 0.013 | 0.020 | 0.020 | 0.040 |

| 1.00 | 1.60 | 0.008 | 0.010 | 0.013 | 0.016 | 0.016 | 0.025 | 0.025 | 0.045 |

| 1.60 | 2.50 | 0.010 | 0.013 | 0.016 | 0.020 | 0.020 | 0.032 | 0.032 | 0.050 |

| 2.50 | 4.00 | 0.013 | 0.016 | 0.020 | 0.025 | 0.025 | 0.040 | 0.040 | 0.056 |

| 4.00 | 6.30 | 0.016 | 0.020 | 0.025 | 0.032 | 0.032 | 0.050 | 0.050 | 0.063 |

6.30 & over

(Multiply by) | x .004 | x .005 | x .005 | x .008 | x .008 | x .010 |

Table 12. Summary of RMA Drawing

Designations Extruded Rubber Products

| RMA Class | Dimensional Tolerance* Table 13 | CutLength Tolerance* Table 16 | SplicedLength Tolerance* Table 16 | MandrelCured* Table 20 |

| 1 | E1 | L1 | S1 | EN1 |

| 2 | E2 | L2 | S2 | EN2 |

| 3 | E3 | L3 | S3 | EN3 |

| 4 | – | – | – | – |

Table 13. Standard Cross-Sectional Tolerance

RMA Class |

| Drawing Designation | |

| Dimensions (in Millimeters) |

| Above | Up to and including | | 0 | 1.5 | | 1.5 | 2.5 | | 2.5 | 4.0 | | 4.0 | 6.3 | | 6.3 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 |

|

| | +0.15 | +0.25 | +0.40 | | 0.20 | 0.35 | 0.50 | | 0.25 | 0.40 | 0.70 | | 0.35 | 0.50 | 0.80 | | 0.40 | 0.70 | 1.00 | | 0.50 | 0.80 | 1.30 | | 0.70 | 1.00 | 1.60 | | 0.80 | 1.30 | 2.00 | | 1.00 | 1.60 | 2.50 | | 1.30 | 2.00 | 3.20 |

|

RMA Class |

| Drawing Designation | |

| Dimensions (in Inches) |

| Above | Up to and including | | 0 | 0.06 | | 0.06 | 0.10 | | 0.10 | 0.16 | | 0.16 | 0.25 | | 0.25 | 0.39 | | 0.39 | 0.63 | | 0.63 | 0.98 | | 0.98 | 1.57 | | 1.57 | 2.48 | | 2.48 | 3.94 |

| | +0.006 | +0.010 | +0.015 | | 0.008 | 0.014 | 0.020 | | 0.010 | 0.016 | 0.027 | | 0.014 | 0.020 | 0.031 | | 0.016 | 0.027 | 0.039 | | 0.020 | 0.031 | 0.051 | | 0.027 | 0.039 | 0.063 | | 0.031 | 0.051 | 0.079 | | 0.039 | 0.063 | 0.098 | | 0.051 | 0.079 | 0.126 |

|

Table 16. Cut Length tolerance for unspliced extrusion

RMA Class |

| Drawing Designation. | |

| Length (in Millimeters) |

| Above | Up to and including | | 0 | 40 | | 40 | 63 | | 63 | 100 | | 100 | 160 | | 160 | 250 | | 250 | 400 | | 400 | 630 | | 630 | 1000 | | 1000 | 1600 | | 1600 | 2500 | | 2500 | 4000 | | 4000 |

| | +0.7 | +0.04 | +1.6 | | 0.08 | 1.3 | 2.0 | | 1.0 | 1.6 | 2.5 | | 1.3 | 2.0 | 3.2 | | 1.6 | 2.5 | 4.0 | | 2.0 | 3.2 | 5.0 | | 2.5 | 4.0 | 6.3 | | 3.2 | 5.0 | 10.0 | | 4.0 | 6.3 | 12.5 | | 5.0 | 10.0 | 16.0 | | 6.3 | 12.5 | 20.0 | | 0.16% | 0.32% | 0.50% |

|

| Length (in Inches) |

| Above | Up to and including | | 0 | 1.6 | | 1.6 | 2.5 | | 2.5 | 4.0 | | 4.0 | 6.3 | | 6.3 | 10.0 | | 10.0 | 16.0 | | 16.0 | 25.0 | | 25.0 | 40.0 | | 40.0 | 63.0 | | 63.0 | 100.0 | | 100.0 | 160.0 | | 160.0 |

| | +0.03 | +0.04 | +0.06 | | 0.03 | 0.05 | 0.08 | | 0.04 | 0.06 | 0.10 | | 0.05 | 0.08 | 0.13 | | 0.06 | 0.10 | 0.16 | | 0.8 | 0.13 | 0.20 | | 0.10 | 0.16 | 0.25 | | 0.13 | 0.20 | 0.40 | | 0.16 | 0.25 | 0.50 | | 0.20 | 0.40 | 0.63 | | 0.25 | 0.50 | 0.80 | | 0.16% | 0.32% | 0.50% |

|

Table 18. Spliced Length Tolerances

Tolerance Table In Inch Calculator

RMA

Class |

| Drawing Designation | |

| Millimeters |

| Above | Up to and including | | 0 | 250 | | 250 | 400 | | 400 | 630 | | 630 | 1000 | | 1000 | 1600 | | 1600 | 2500 | | 2500 | over |

| | +302 | +3.2 | +7.1 | | 4.0 | 7.1 | 8.0 | | 5.0 | 8.0 | 9.0 | | 6.3 | 9.0 | 10.0 | | 8.0 | 10.0 | 11.2 | | 10.0 | 11.2 | 12.3 | | 012.5 | 12.5 | 16.0 |

|

| Inches |

| Above | Up to and including | | 0 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 | | 100 | over |

| | +.13 | +.25 | +.28 | | .16 | .28 | .32 | | .20 | .32 | .36 | | .25 | .36 | .40 | | .32 | .40 | .45 | | .40 | .45 | .50 | | .50 | .50 | .53 |

|

Table 20. Tolerances on Internal Dimensions

of Mandrel-Supported Extrusions

RMA

Class |

| Drawing Designation | |

Nominal Dimensions

(in Millimeters) |

| Above | Up to and including | | 0 | 4 | | 4 | 6.3 | | 6.3 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 | | 100 | 160 | | 160 |

| | +0.20 | +0.20 | +0.35 | | 0.20 | 0.25 | 0.40 | | 0.25 | 0.35 | 0.50 | | 0.35 | 0.40 | 0.70 | | 0.40 | 0.50 | 0.80 | | 0.50 | 0.70 | 1.00 | | 0.70 | 0.80 | 1.30 | | 0.80 | 1.00 | 1.60 | | 1.00 | 1.30 | 2.00 | | 0.6% | 0.8% | 1.2% |

|

Nominal Dimensions

(in Inches) |

| Above | Up to and including | | 0 | 0.16 | | 0.16 | 0.25 | | 0.25 | 0.40 | | 0.40 | 0.63 | | 0.63 | 1.00 | | 1.00 | 1.60 | | 1.60 | 2.50 | | 2.50 | 4.00 | | 4.00 | 6.30 | | 6.30 |

| | +0.008 | +0.08 | +0.014 | | 0.008 | 0.010 | 0.016 | | 0.010 | 0.014 | 0.020 | | 0.014 | 0.016 | 0.028 | | 0.016 | 0.020 | 0.032 | | 0.020 | 0.028 | 0.040 | | 0.028 | 0.032 | 0.051 | | 0.032 | 0.040 | 0.063 | | 0.040 | 0.051 | 0.079 | | 0.6% | 0.8% | 1.2% |

|

Don't miss anything! Subscribe to our newsletter.

Get the latest articles, reports and industry news.

YOU MIGHT ALSO LIKE

6 Reasons to Use Custom Rubber Parts in the Glass and Glazing Industry

Architects and engineers are constantly pushing the limits of what architectural glass and glazing systems can do.

More details

Tolerance Table In Inch Size

Rubber extrusions sample kit

A selection of commonly used rubber materials and custom extruded shapes we manufacture for commercial glazing, medical, food and beverage, and HVAC applications. See, touch and feel silicone and EPDM swatches of various colors, hardness’s and specifications as well as extruded samples.

Tolerance Table Inches

More details

Tolerance Table In Inch Measurements

7 MISTAKES TO AVOID WHEN DESIGNING RUBBER EXTRUSIONS

Tolerance Table In Inch Chart

Whether launching a new product line, improving an existing product’s performance or reducing manufacturing costs, manufacturers of curtain walls and architectural glass and glazing go to great lengths to create new or improved extrusion designs.

Tolerance Table In Inch Cm

More details